Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

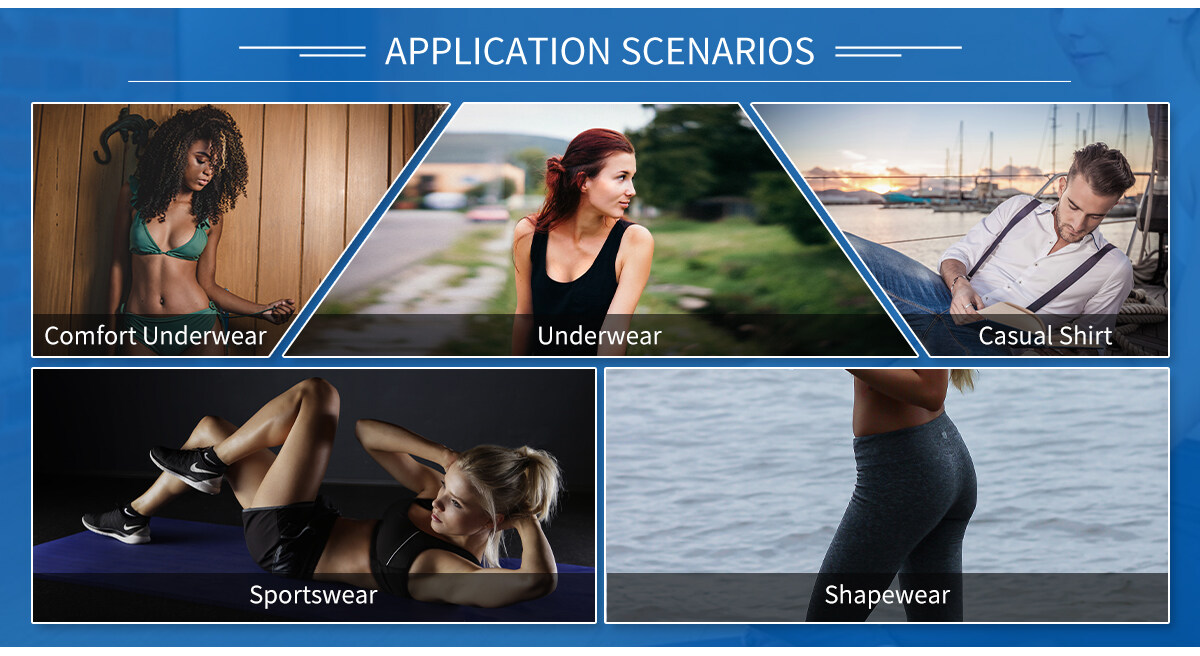

With high adhesive power, 6855D can operate in low temperature. Heat sensitive fabrics that not available for high temperature operation can be bonded with this adhesive.

With high adhesive power, 6855D can operate in low temperature. Heat sensitive fabrics that not available for high temperature operation can be bonded with this adhesive.

Properites

| Article | Width | Gauge | Softening Point | Temperature | Pressure | Recovery | Hand | Modulus (40%) | Modulus (100%) | Wash |

|---|---|---|---|---|---|---|---|---|---|---|

| 6855D | 1520mm | 0.05mm0.08mm0.1mm | 80℃ | 130-160 C | 3.5-5kg | 96% | Medium | 2.46N-0.05mm | 3.06N-0.05mm | Up to 40'C |

Applicaiton of heat sentitive adhesive

Hot-melt adhesive films have a certain difference between high and low temperatures, mainly because of their melting point, that is, the difference in use temperature. Generally, those below 80°C are low-temperature hot-melt adhesive films, and those above 130°C are high-temperature hot-melt adhesive films.

The types of the low-temperature hot-melt adhesive film mainly include low-temperature TPU hot-melt adhesive film and EVA hot-melt adhesive film. The melting point of low-temperature TPU hot-melt adhesive film is mainly around 70 degrees Celsius. Different models will have certain differences, and the melting point can be lower. To forty or fifty degrees. The melting point of EVA hot melt adhesive film is 70 degrees Celsius, which is also a relatively low temperature.

Regardless of whether it is a low-temperature hot-melt adhesive film or a medium-high temperature hot-melt adhesive film, they all have the basic characteristics of hot-melt adhesive films, including good adhesive performance, non-toxic, non-aldehyde and harmless environmental protection and safety performance. Low-temperature TPU hot-melt adhesive film has no elasticity. TPU material is a relatively special material. The elasticity will increase with the increase of melting point, and low-temperature TPU is the worst elasticity. Low temperature TPU hot melt adhesive film has good washing resistance. Contrary to the low-temperature TPU hot-melt adhesive film, the EVA hot-melt adhesive film has elasticity, but its washing resistance is poor. Because the characteristics of the two are different, their applications will also be different.

Low-temperature TPU hot-melt adhesive film and EVA hot-melt adhesive film are both used as low-temperature hot-melt adhesive films. What they have in common is that they can only be used in situations where high-temperature pressing materials cannot be used or are limited by the upper limit of the heating equipment temperature. The specific low-temperature TPU hot-melt adhesive film is mainly used on ordinary cloth and leather materials, while the EVA hot-melt adhesive film is mainly used on sponge and foaming products.